Your Partner in

Gear Manufacturing

Spur Gears

Spur gears are the most common and simplest type of gear. They have straight teeth cut parallel to the gear’s axis, making them ideal for transmitting power and motion between two parallel shafts. Spur gears are known for their high efficiency and reliability, and they are widely used in a variety of industries, including automotive transmissions, gear pumps, and industrial machinery.

Helical Gears

Helical gears feature teeth that are cut at an angle to the gear’s axis. This angled design allows for a larger contact area between teeth, which results in quieter, smoother operation and the ability to transmit motion at higher speeds compared to spur gears. Helical gears are often used in automotive transmissions, printing presses, and high-speed machinery.

Bevel Gears

Bevel gears are cone-shaped gears designed to transmit power between two shafts that intersect at an angle, typically 90 degrees. Their unique form allows for a change in the axis of rotation, making them essential for applications like differentials in cars, hand drills, and railway drives where power needs to be transferred at an angle.

Worm Gears

A worm gear system consists of a worm (which looks like a screw) and a worm wheel. This unique pairing provides a right-angle drive and an extremely high reduction ratio in a compact space. Worm gears are also known for their self-locking capability, meaning the worm wheel cannot turn the worm, which makes them ideal for applications requiring a secure hold, such as lifting equipment and conveyor systems.

Internal Gears

An internal gear is a gear with teeth on the inside of a cylinder or ring. They are typically paired with a smaller spur gear (called a pinion) that meshes inside the ring. This configuration offers a very compact design and is highly efficient. Internal gears are commonly found in planetary gear systems, bicycle hub gears, and certain industrial mixers.

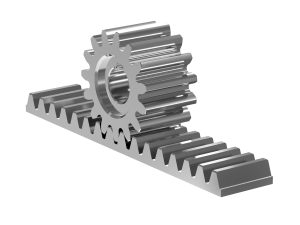

Rack and Pinion Gears

A planetary gear system consists of a central “sun” gear, several “planet” gears that rotate around the sun gear, and an outer “ring” gear. This unique arrangement allows for extremely high torque and a compact design. Planetary gears are commonly used in automatic transmissions, power drills, and construction equipment where high torque and precise speed reduction are required in a limited space.

Planetary Gears

A planetary gear system consists of a central “sun” gear, several “planet” gears that rotate around the sun gear, and an outer “ring” gear. This unique arrangement allows for extremely high torque and a compact design. Planetary gears are commonly used in automatic transmissions, power drills, and construction equipment where high torque and precise speed reduction are required in a limited space.

Gear Cutting Services

Have a question about our gear cutting services? Use the form below to get in touch. We’re here to help with any inquiries you have regarding your project needs.